Wine bottles are one of the most common containers used for storing wine. In this article, we explore how wine bottles are made from start to finish. Glass is a material that can be molded into almost any shape, which is why it’s so widely used in the production of different products. Manufacturers use glass to make everything from drinking glasses and windows to light bulbs and even glass bottles for alcoholic beverages. In this step-by-step guide, we look at the process of making wine bottles from start to finish. These images will show you exactly what happens when you buy wine in a bottle; from converting raw materials such as sand and limestone into finished product, to assembling the final product with a label and cork.

How Wine Bottles Are Made

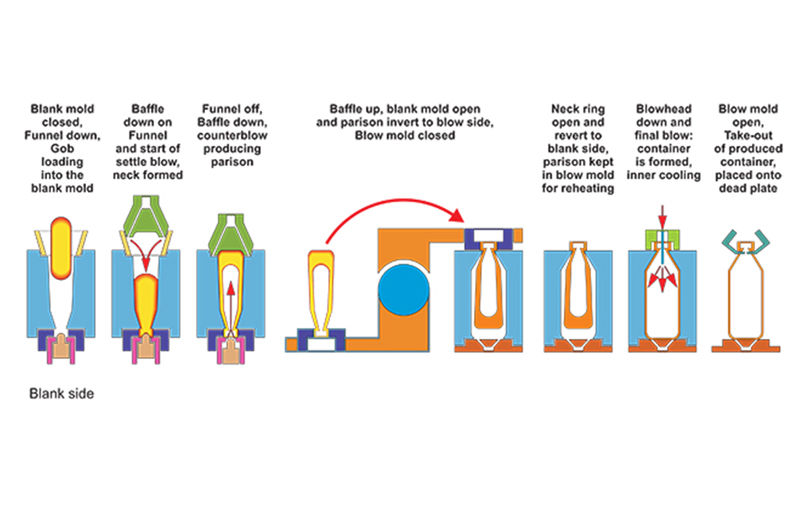

Wine bottles are made from molten glass, in a process called glass blowing. This is a very old process that dates back to the Roman Empire. First, the manufacturer will take a large supply of molten glass, usually kept at around 900 degrees Fahrenheit, and blow it into a tube. The shape of this tube can vary depending on the type of wine bottle being made. One of the most important aspects of this process is controlling the amount of air that goes into the glass. Too much air will weaken the glass, causing it to break easily. Too little air will result in a product that’s too thick and heavy.

The Manufacturing Process

Now that the glass has been blown into a tube, the next step is to cut it into the correct length. This part of the process is called “tube forming”. The length of the tube will depend on the type of wine bottle being made. The next part of the manufacturing process is “neck forming”. Here, the tube is cut to the correct length and the top of the tube is flattened out. A “mandrel” is used to give the tube a “neck” shape. The mandrel is then removed, and the tube is ready for the next step. The next step is called “annealing”. This is the process of cooling down the tube so that it is soft and malleable. The last step in the manufacturing process is “forming”. During this phase, the tube is formed into the correct shape. This process often uses machines that apply immense pressure to the soft glass, shaping it into its required form.

Raw Material Processing

The raw materials used to make glass are sand and limestone. These are combined with other additives such as soda ash, limestone, and caustic soda. The ingredients are heated to a very high temperature to create molten glass, which is then cooled to form a solid. A typical bottle of wine is expected to last for around 3-5 years. Therefore, the glass used to make it must be of the highest quality. In order to produce a product that’s safe for people to drink from, manufacturers must ensure that no impurities are present in the glass. They do this by using a process called “fluxing”. During this phase, the glass is placed in a container of activated carbon, which absorbs any impurities.

Glass Blowing

We’ve already discussed the glass blowing process above. However, it’s worth noting that the temperature of the molten glass will vary depending on the type of wine being bottled. Red wine, for example, is made from a type of glass that is much cooler than the blue wine bottle. The temperature of the glass depends on the color of the wine and the type of grape used to make it. For example, white wine is made from the grape variety known as “sauvignon blanc”. Therefore, the temperature of the glass used to make white wine bottles is lower than the temperature used to make red wine bottles.

Decoration and Final Product Wrapping

Once the wine bottle has been formed, the next step is decoration. Again, this process will vary depending on the type of wine being made and the desired design. For example, some bottles are decorated with images of vines, while others are printed with the name of the wine and the year it was made. Once the bottle has been decorated, it is ready to be wrapped up in a cardboard box. The wrapping process is very important, as it keeps the wine from being damaged during transportation. Once the bottles have been wrapped, they are ready to be sent to retailers. In order to make sure that the bottles arrive in good condition, they are often transported on a pallet.

Bottling Importance of quality control in manufacturing

As you can see, making wine bottles is a complicated process. This is why manufacturers have to be extremely careful when designing and producing the product. Any small mistake can have disastrous consequences; the bottle could break during transport, or a wine drinker could be injured while opening the bottle. This is why it’s so important to have a quality control system in place. It’s the only way to make sure that the bottles are being produced to the correct specification. It also means that the product is being manufactured safely and that the bottles are not being contaminated by impurities. These are important considerations, as the quality of the bottle can affect the taste of the wine. It’s why wine glasses are made from high-quality glass; it doesn’t affect the taste of the wine, but it does make it more enjoyable.