-

Arabic

-

English

-

French

-

Malagasy

-

Portuguese

-

Russian

-

Spanish

-

Thai

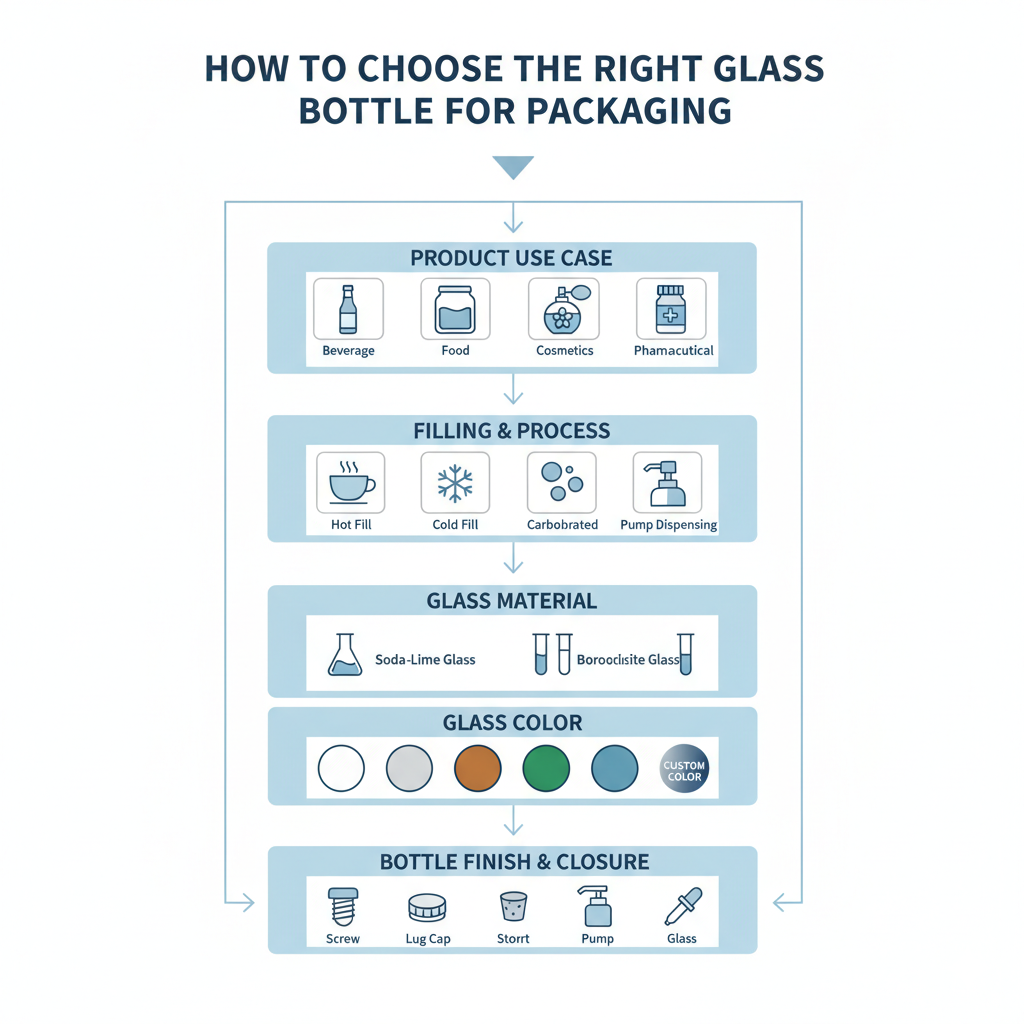

Choosing a glass bottle is not a design-only decision. It affects filling performance, shelf life, breakage rate, and the total landed cost of packaging. Many sourcing problems do not show up during sampling. They appear later, when production starts and you see leakage, scuffs, cap issues, or transport damage.

If your team is comparing packaging options and searching for Types of glass bottles, the fastest path is not memorizing shape names. It is choosing based on what actually controls outcomes: the use case, glass material, color, and closure compatibility.

The three mistakes that cause most glass bottle failures

Mistake 1: Choosing by appearance instead of process

A bottle can look premium and still fail under hot fill, carbonation pressure, or high-speed capping torque. The filling method sets the performance requirements, not the shape.

Mistake 2: Picking color without thinking about product stability

Clear glass works when product visibility matters and the formula is stable. For sensitive formulas, the wrong color can shorten shelf life.

Mistake 3: Requesting price before confirming the complete specification

MOQ, lead time, closure fit, decoration durability, packaging method, and defect limits often drive cost more than the bottle itself. If the spec is vague, quotes are not comparable.

If you fix these three issues early, selection becomes faster and sourcing becomes predictable.

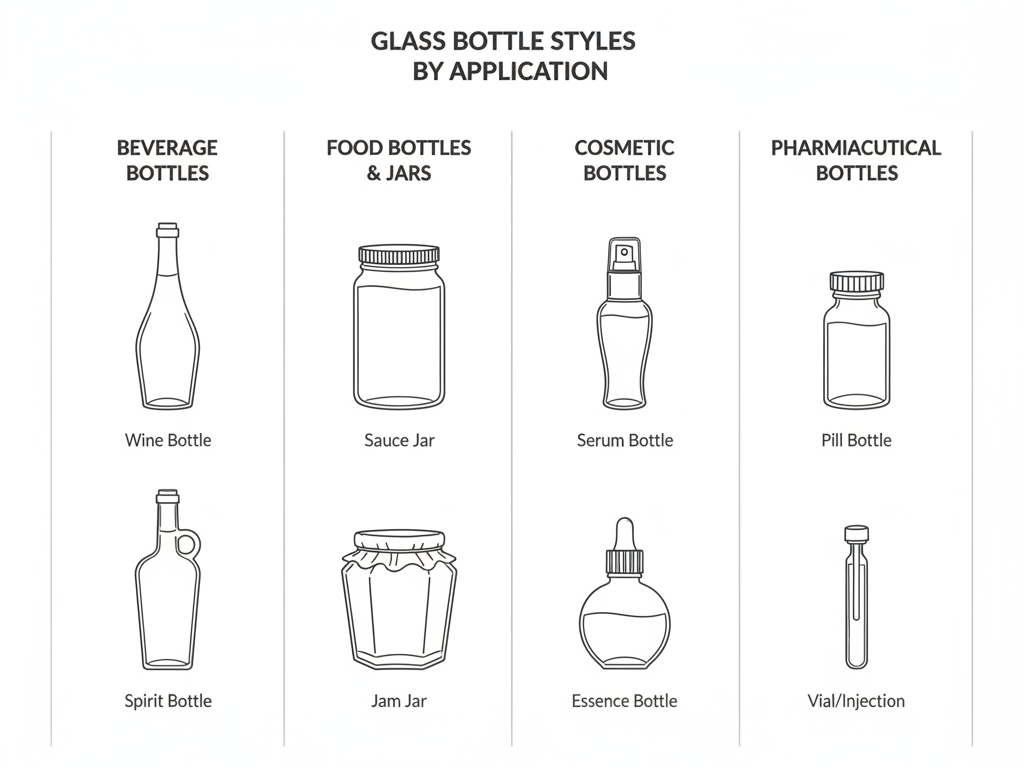

Glass bottles by use case

Start with the product category because it determines the stress the bottle must survive.

Beverage bottles

Beverage bottles are designed around production reality: line speed, repeat handling, and sometimes internal pressure.

Carbonated drinks and beer

These require bottles that handle internal pressure and maintain seal under load. Consistent wall thickness and finish accuracy matter because small variations can create sealing issues at high speed.

Juice, tea, and functional drinks

Many of these products use hot fill or undergo thermal processing. Temperature changes can create vacuum forces and stress the closure. If you hot-fill, confirm the thermal window and make sure the cap liner performs under heat.

Water

Lightweight designs reduce shipping cost, but only when drop resistance stays within target. Lightweight should be a controlled decision, not an assumption.

Buyer checks for beverage bottles:

- Fill method: cold fill, hot fill, pasteurization

- Internal pressure needs

- Finish and cap compatibility

- Breakage targets for distribution

Food bottles and jars

Food packaging is usually about sealing reliability and consumer handling.

Sauces and condiments

Neck design affects pour control and capping reliability. Consistent finish dimensions prevent cross-threading and torque variation.

Edible oils

Oil often exposes weak seals quickly, especially after temperature swings during shipping. Liner choice and torque control are as important as the glass.

Honey, jam, and spreads

Wide-mouth jars improve filling efficiency and consumer usability. Vacuum performance and liner selection determine long-term sealing.

Buyer checks for food packaging:

- Product viscosity and pour or scoop behavior

- Seal type: screw cap or lug style

- Thermal process: hot fill or other heat exposure

- Packaging strength for stacking and transport

Cosmetic bottles

Cosmetic packaging demands both performance and brand feel. Dispensing compatibility is the most common source of problems.

Serums and facial oils

Dropper systems require precise finish dimensions so the dropper seats consistently and does not leak. If the formula is light-sensitive, color selection matters early.

Lotions and liquid skincare

Pump fit is a system decision. Finish type, collar fit, gasket choice, and dip tube length must be confirmed together.

Fragrance

These bottles often use thicker bases and higher decoration expectations. Finish accuracy still matters because sprayer compatibility and leak performance depend on it.

Buyer checks for cosmetics:

- Dispensing system: pump, dropper, sprayer

- Decoration durability targets

- Formula compatibility with gasket and liner materials

- Light protection needs

Pharmaceutical and health-related bottles

These products often require tighter expectations on defects, tolerances, and stability. Amber bottles are common when light exposure can reduce potency. Consistent inspection standards and closure compatibility become more important because the cost of failure is higher.

Buyer checks:

- Light protection requirement

- Closure and liner performance expectations

- Inspection criteria and defect limits

- Any market-specific documentation you need

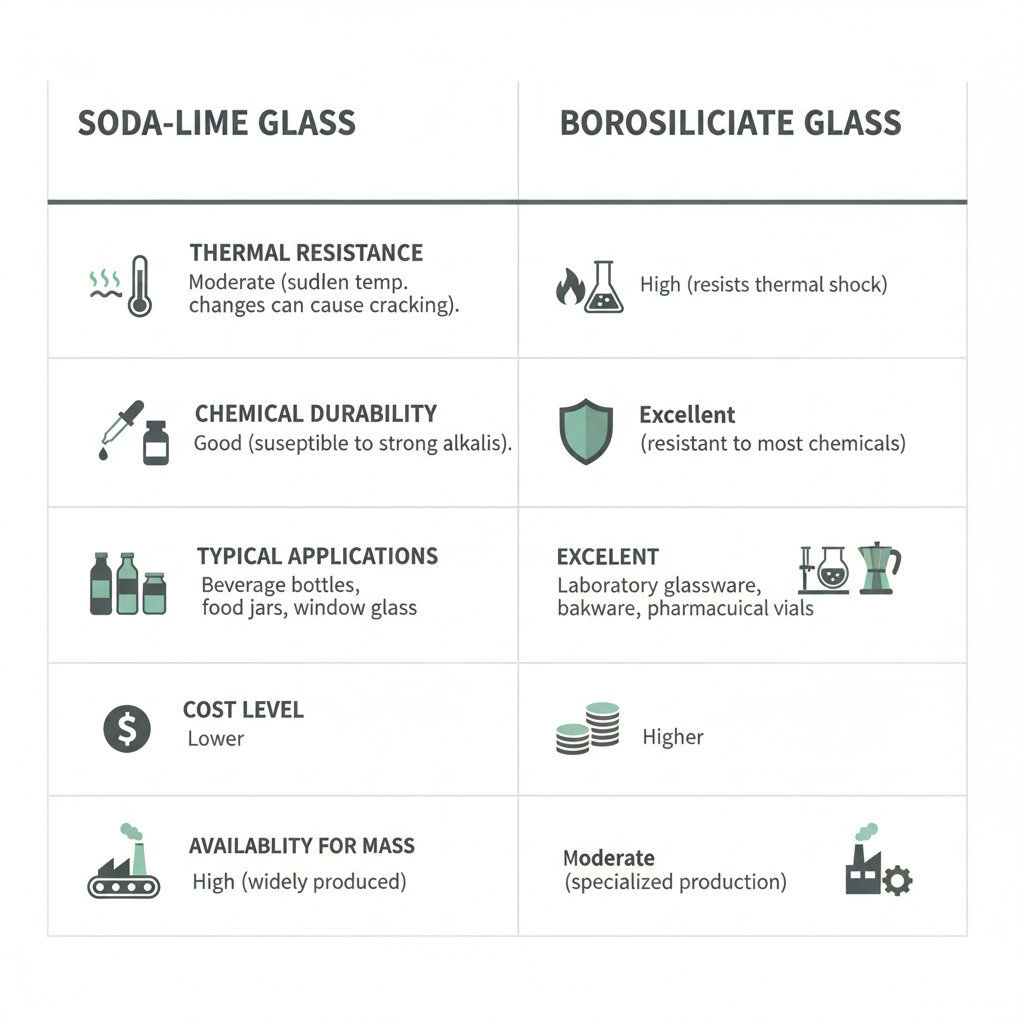

Glass bottles by glass material

Material selection is usually driven by chemical durability and thermal performance.

Soda-lime glass

Soda-lime glass is the most common option for packaging because it balances cost, availability, and performance. It works well for a wide range of food, beverage, and many personal care products.

Best fit for:

- Most beverages and foods

- Many personal care products

- High-volume packaging with stable supply needs

What to confirm:

- Thermal exposure if you hot-fill

- Breakage targets for your distribution conditions

Borosilicate glass

Borosilicate glass is chosen when thermal shock resistance and chemical durability are critical. It is often used for applications with larger temperature swings or higher stability expectations.

Best fit for:

- Packaging exposed to significant temperature changes

- Specialty applications needing higher chemical durability

What to confirm:

- Availability in your target capacity and finish type

- Cost impact and lead time compared with standard options

The practical takeaway is simple: choose the material that matches the real constraints. Over-specifying increases cost. Under-specifying increases risk.

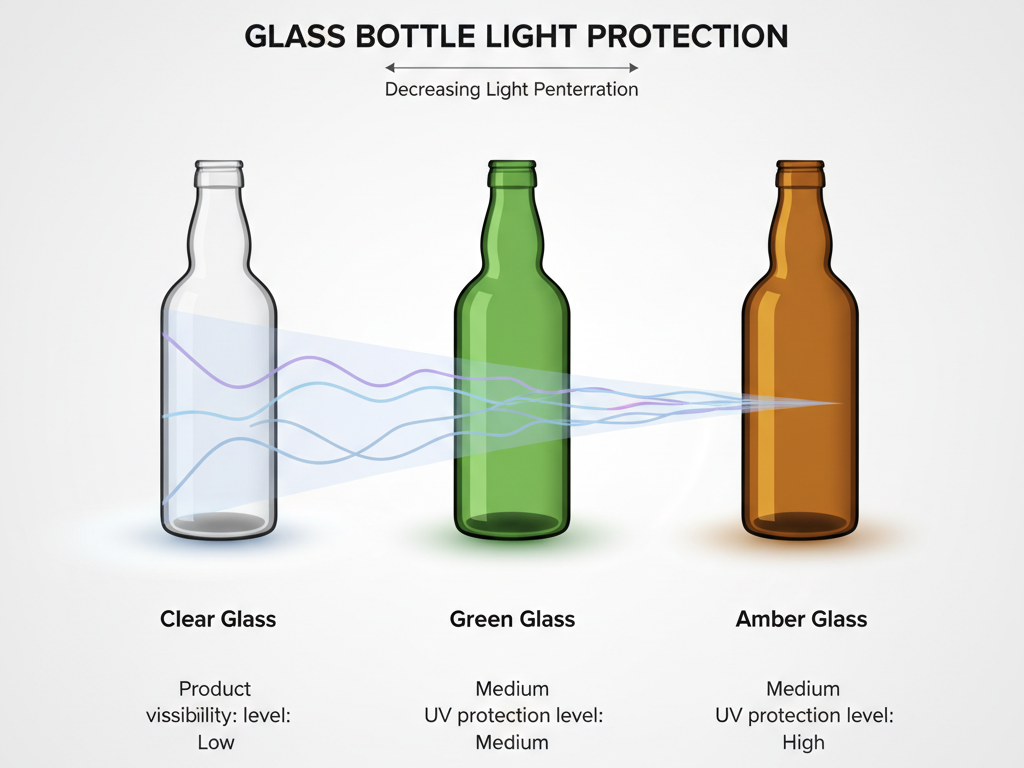

Glass bottles by color

Color is not only branding. It also affects product protection and shelf stability.

Clear bottles

Clear glass maximizes product visibility and supports premium shelf presentation. It works best when the formula is stable under light exposure.

Use when:

- Product appearance drives purchase

- Light sensitivity is not a main risk

Amber bottles

Amber glass provides strong protection against UV and high-energy visible light. It is common for products where light exposure affects flavor, potency, or shelf life.

Use when:

- The product is sensitive to light

- Shelf life depends on limiting exposure during storage and display

Green and other colored bottles

Green, blue, and custom colors provide brand differentiation and partial light reduction. They are common in wine, spirits, and premium personal care.

Use when:

- Brand identity is a priority

- Partial light reduction is beneficial

A buyer rule that prevents late changes: decide whether light protection is required before you lock the bottle design and quote.

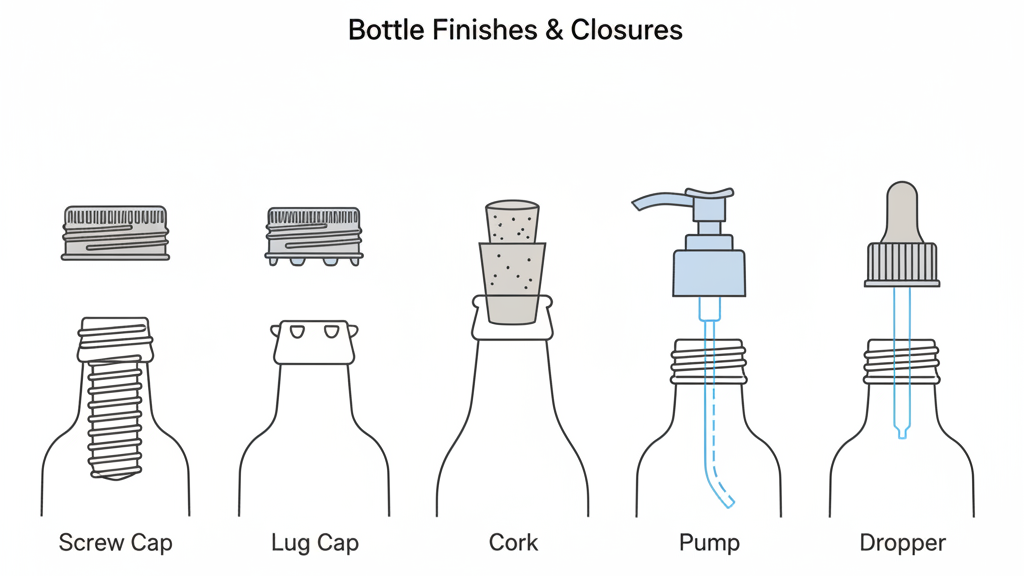

Bottle finishes and closure systems

Many sourcing problems happen because the bottle and closure are treated as separate purchases. In practice, they must be selected as a matched system.

Screw caps

Common for beverages, foods, and personal care. Performance depends on thread accuracy, liner selection, and torque control. If tamper evidence is required, confirm it early because it affects the finish choice.

Lug and twist-off closures

Common for food jars and products relying on vacuum sealing. Cap liner and vacuum performance must be validated, especially when products are filled hot.

Cork finishes

Common for spirits and premium beverages. Neck tolerances and top load performance matter during shipping and handling.

Pumps, droppers, and sprayers

These require finish precision and real component fit testing. Confirm collar fit, gasket choice, leak resistance, and dip tube length using production-intent components.

A practical rule: choose the closure first, then choose the finish that matches it. This approach reduces leaks, cross-threading, and fit surprises.

When custom glass bottles are worth it

Custom development is not only about a new shape. It is about creating packaging that performs reliably, supports the brand, and is harder to copy.

Custom is typically worth it when:

- The product is a long-term core SKU

- Shelf presence matters and standard shapes look generic

- You need a specific label panel, grip feel, or base weight

- You want tighter control over supply consistency

Customization can include decoration choices that affect durability and brand perception:

- Screen printing for durable branding

- Coating and color effects for premium presentation

- Frosted finishes for tactile feel

- Label-ready surfaces for high-speed application

If decoration is important, request samples that reflect real production and define basic durability expectations so the result stays consistent across batches.

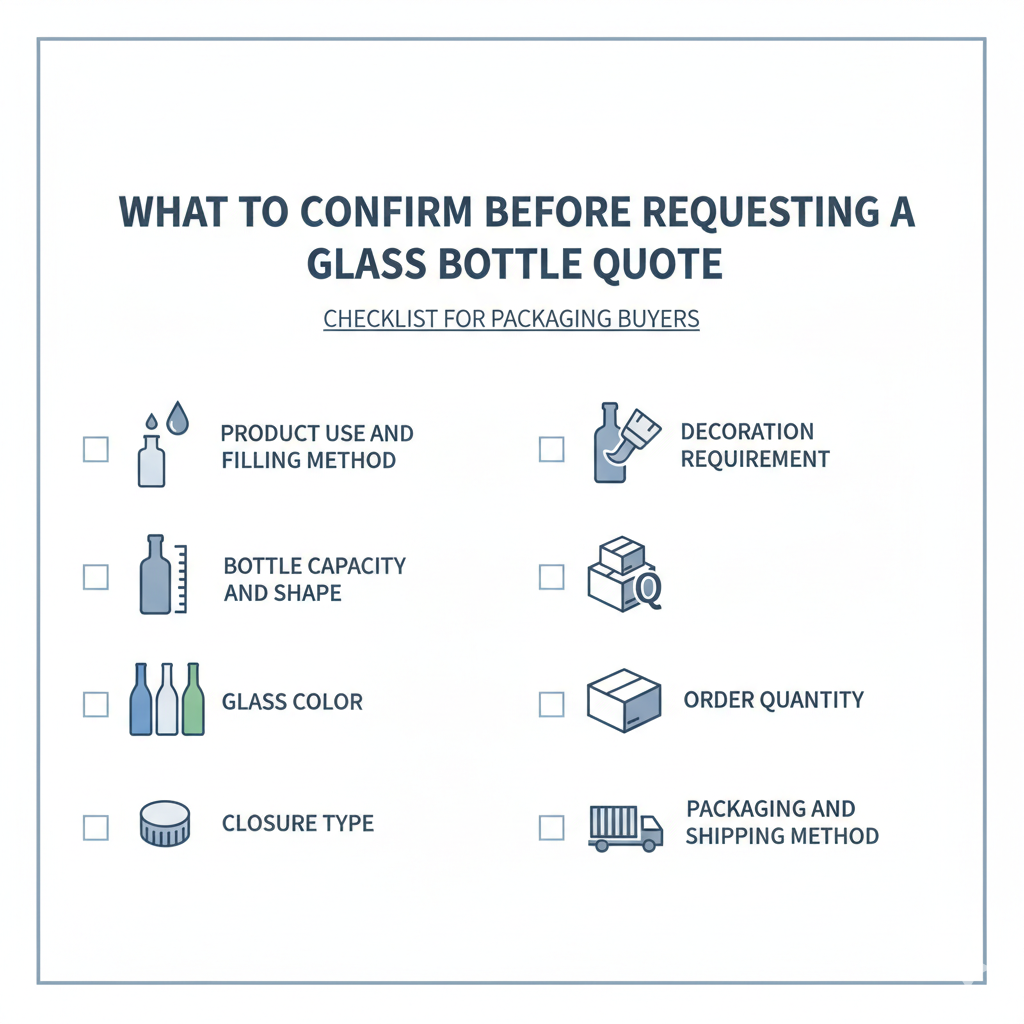

A quote-ready checklist that saves time

If you want accurate quotes and fewer revisions, share these details upfront:

- Product category and fill method

- Target capacity and fill level

- Color requirement

- Closure type and any accessories

- Decoration requirements

- Order quantity and timeline

- Packaging method for shipping: cartons, partitions, pallets

This checklist helps suppliers recommend the correct bottle option, confirm closure fit, and plan protective packaging to reduce breakage.

Sampling, MOQ, and lead time planning

Stock bottles are a good fit when speed matters, MOQ needs to stay lower, or you want to test market response. They also reduce development time because the bottle is already proven.

Custom molds make sense when the product will run at stable volume and you want distinct shelf presence. The value is long-term, not only visual.

Sampling should validate more than appearance:

- Closure fit and leak resistance

- Label application or decoration durability

- Packaging method and transport protection

- Consistency of weight and key dimensions

Samples should reflect production intent. A sample that looks good but cannot be repeated consistently does not reduce risk.

Conclusion

Glass bottle selection sounds simple, but buyers get better results when they treat it as a system decision: the use case, glass material, color, and closure compatibility. When those pieces match, you reduce line issues, protect product stability, and lower breakage during distribution.

If you want sourcing to move quickly, define the process requirements first, then lock the closure system, and only then finalize the bottle style and decoration. That sequence delivers packaging that looks right and performs right.