-

Arabic

-

English

-

French

-

Malagasy

-

Portuguese

-

Russian

-

Spanish

-

Thai

Glass plays a unique role in modern packaging because it protects product quality while supporting premium branding. But glass is not a universal best choice—weight, breakage risk, and distribution realities matter.

This guide helps you decide when glass makes sense, what to watch out for, and how to match the right glass bottle or jar to your product. If you already know what you need, you can browse PackaFill’s wholesale glass containers and accessories, or start a custom project with private mold development.

Quick paths

- Browse glass bottles and jars (standard styles and sizes)

- Choose closures and dispensing options (caps, pumps, sprayers, etc.)

- Start a custom glass packaging project (OEM/ODM + private mold)

What makes glass different in packaging

Glass is non-porous and chemically stable for most everyday packaging needs, which helps reduce unwanted odor transfer and protects taste and aroma-sensitive products. It also delivers strong barrier performance against moisture and gases compared with many common packaging materials, and it supports high-clarity presentation for retail shelves.

Where glass stands out most is the balance of:

- Product integrity (taste, aroma, formula stability)

- Shelf presence (clarity, weight-in-hand, premium feel)

- Format flexibility (bottles, jars, wide-mouth and narrow-neck options)

Where glass packaging performs best

Glass packaging tends to be a strong fit in these situations:

Products where taste, aroma, and purity matter

Common examples include sauces, honey, spices, edible oils, beverages, and specialty foods—especially when you want a clean, neutral container that doesn’t add odors.

Brands that rely on shelf visibility and premium cues

Clear or tinted glass supports “what you see is what you get” positioning. For many consumer products, glass communicates quality without needing extra explanation.

Formulas that benefit from stronger barrier protection

If your product is sensitive to moisture or oxygen exposure after filling, the right glass format paired with a suitable closure can help improve shelf stability (final results are always product- and closure-dependent).

High-impact handling environments

If your product is frequently dropped, shipped loose, or handled in rough last-mile conditions, breakage risk can become a major cost driver. Protective packaging, carton design, and palletization become non-negotiable.

Ultra-low-cost positioning

If your retail price point is extremely tight, glass may not be the most economical option after freight and protective packaging are included.

Practical takeaway: glass is best when product integrity + brand value outweigh weight and handling trade-offs.

The most common glass packaging applications we support

PackaFill supplies wholesale and custom glass bottles and jars for multiple industries, with closure and accessory options to match different use cases.

Food packaging in glass

- Jars for honey, jam, sauces, spices, pickles, dry foods

- Wide-mouth options for easy filling and consumer use

- Closure choices for freshness and merchandising

Beverage packaging in glass

- Bottles for juice, kombucha, smoothies, water, beer-style formats

- Options that support label presentation and brand differentiation

Cosmetics and personal care packaging in glass

- Bottles for serums, facial oils, toners, fragrance formats

- Compatible dispensing solutions such as pumps and sprayers (format-dependent)

Pharmaceutical and health-related packaging in glass

Bottles and small containers for health products where packaging stability and consistency matter (requirements vary by market and product type)

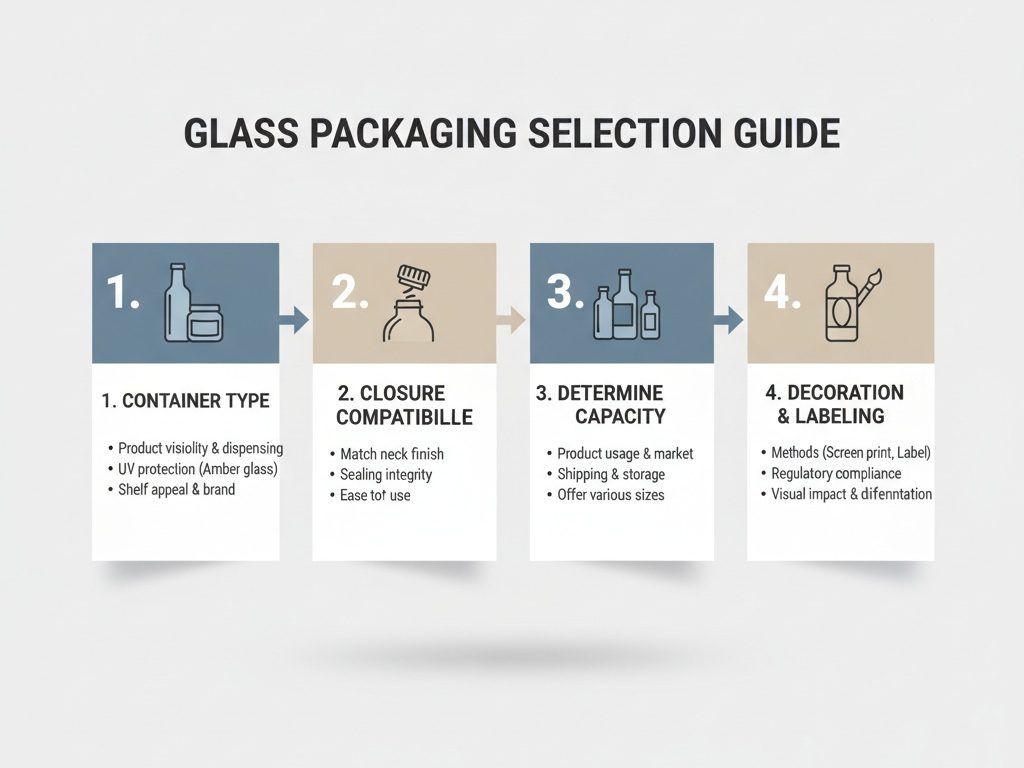

How to choose the right glass container

This is the section most competitor pages miss. Use it to avoid “nice-looking bottle, wrong-for-the-job” mistakes.

Step 1 — Decide between a bottle and a jar

Choose a bottle when you need controlled pouring or dispensing.

Choose a jar when you need wide-mouth access, spooning, scooping, or thicker products.

Step 2 — Match neck finish and closure to real usage

A great container fails if the closure doesn’t fit your product and customer workflow.

Consider:

- Twist caps vs lug caps (common in food)

- Droppers, pumps, sprayers (common in cosmetics)

- Tamper-evident needs (market- and channel-dependent)

PackaFill can supply matching accessories to support a consistent packaging set.

Step 3 — Choose capacity based on consumption pace and shelf positioning

Don’t choose a size only from competitors’ photos. Size affects:

- Price perception

- Repeat purchase cycle

- Shipping case count and pallet efficiency

Step 4 — Choose glass color and decoration plan

Clear glass is great for visibility. Tinted options can support brand style and may help with light-sensitive positioning (final protection depends on product and overall packaging design).

Decoration options are typically planned around:

- Labeling

- Printing (when applicable)

- Custom shape/embossing via private mold (project-based)

Glass packaging and sustainability in real-world terms

Glass is widely recognized for recyclability, but sustainability outcomes depend on collection systems and transportation realities, as the environmental impact of packaging materials is shaped by how packaging is collected, moved, and processed in the real world. For brands, the practical sustainability story often comes down to:

- Recyclable material choice

- Lightweighting where appropriate

- Refill/reuse concepts when your channel supports it

- Reducing breakage and returns through pack-out optimization

We can help you select stable formats and packaging approaches that support shipping and handling consistency (project-dependent).

What you can customize with PackaFill

If standard items don’t match your brand or filling line, custom work typically starts with clear decisions about shape, closure compatibility, and decoration planning.

Customization options typically include

- Bottle/jar shape and capacity

- Glass color (subject to feasibility and MOQ)

- Neck finish matched to target closure

- Logo/branding approach (labeling and project-specific options)

OEM/ODM and private mold development

PackaFill supports OEM/ODM projects from concept to production and can develop private molds for brand-exclusive shapes (scope depends on project requirements and volumes).

Call to action

- If you already have a target container: send capacity + closure type + estimated order volume

- If you are still choosing: tell us your product type, filling method, and sales channel, and we’ll recommend suitable bottle/jar directions

Common questions about glass in packaging

Is glass always better than plastic packaging?

Not always. Glass often wins on product integrity and shelf presence, but weight and breakage risk can make it a poor fit for some distribution models.

What is the biggest risk when switching to glass packaging?

Usually logistics: weight, pack-out design, and handling conditions. These need to be planned early to reduce breakage and returns.

Can I get matching caps, pumps, or sprayers with my glass bottle?

Yes—closure and dispensing compatibility depends on the bottle neck finish and the product’s viscosity and usage style. PackaFill supplies accessories as part of a complete packaging set.

Can you make a custom glass bottle or jar for my brand?

Yes. Private mold development is available for brand-exclusive shapes, typically when the project volume supports it.

A practical wrap-up for packaging decisions

Glass packaging works best when product integrity, shelf presentation, and brand perception are more important than minimizing weight or short-term logistics cost. It is not a universal solution, but when matched correctly to product type, distribution conditions, and closure systems, glass delivers long-term value that many materials cannot replicate.

The key is not choosing glass because it looks premium, but choosing the right bottle or jar configuration for how your product is filled, shipped, sold, and used.